Abstract

The utilization of bricks made of styrofoam is expectedly able to be a soundproof for noise control and as a preventive action to reduce the steadily increasing prevalence of hearing loss. This study aimed to assess the use of sound absorption material in which styrofoam was utilized to reduce the noise exposure. In this study, fine aggregates (sand and styrofoam) were made with a mixture of cement with a composition of 1:4 and 1:6, also the addition of polystyrene waste with a percentage of 0%, 20%, 40%, 60%, and 80%. Determination of acoustical property of the mixture was done by testing the sound absorption coefficient (α) using Four Microphones Impedance Tube (ISO 140-3). The results showed that the highest value of absorption coefficient was at a frequency of 800 Hz with an additional 80% styrofoam for the composition of 1:4 at 0.4100 dB and at a frequency of 800 Hz with an additional 40% styrofoam for the composition of 1:6 at 0.5870 dB.

References

1. Daniel E. Noise and hearing loss: A review. Journal of School Health. 2007; 77(5): 225–31.

2. Chadambuka A, Mususa F, Muteti S. Prevalence of noise induced hearing loss among employees at a mining industry in Zimbabwe. African Health Sciences. 2013;13(4): 899–906.

3. Kirchner DB, Evenson E, Dobie RA, Rabinowitz P, Crawford J, Kopke R, et al. Occupational noise-induced hearing loss. Journal of Occupational and Environmental Medicine. 2012; 54(1): 106–8.

4. Kateman E, Verbeek JH, Morata T, Coolsma B, Dreschler W, Sorgdrager B. Interventions to prevent occupational noise induced hearing loss. Cochrane Database of Systematic Reviews. 2009; 8(3): 1-6.

5. Korniejenko K, Fr czek E, Pytlak E, Adamski M. Mechanical Properties of Geopolymer Composites Reinforced with Natural Fibers. Procedia Engineering. 2016; 151: 388–93.

6. Chen D, Li J, Ren J. Study on sound absorption property of ramie fiber reinforced poly(l-lactic acid) composites: Morphology and properties. Composites Part A: Applied Science and Manufacturing. 2010; 41(8): 1012–8.

7. Zulkifli R, Nor MJM, Ismail AR, Nuawi MZ, Tahir MFM. Effect of perforated size and air gap thickness on acoustic properties of coir fibre sound absorption panels. European Journal of Scientific Research. 2009; 28(2): 242–52.

8. Kang CW, Oh SW, Lee TB, Kang W, Matsumura J. Sound absorption capability and mechanical properties of a composite rice hull and sawdust board. Journal of Wood Science. 2012; 58(3): 273–8.

9. Qin L, Qiu J, Liu M, Ding S, Shao L, Lü S, et al. Mechanical and thermal properties of poly(lactic acid) composites with rice straw fiber modified by poly(butyl acrylate). Chemical Engineering Journal. 2011; 166(2): 772–8.

10. Fachrul MF, Yulyanto WE, Merya A. Desain penyusunan peredam kebisingan menggunakan plywood, busa, tray dan sabut pada sumber statis. Makara Journal of Technology. 2011; 15(1): 63–7.

11. Dharmantya MW. Pengaruh porositas pada tingkat redaman suara papan partikel serbuk sekam padi [Skripsi]. Semarang: Jurusan Teknik Mesin Fakultas Teknik Univesitas Diponegoro; 2010. 1-20 p.

12. Ersoy S, Küçük H. Investigation of industrial tea-leaf-fibre waste material for its sound absorption properties. Applied Acoustics. 2009; 70(1): 215–20.

13. Zou Y, Huda S, Yang Y. Lightweight composites from long wheat straw and polypropylene web. Bioresource Technology. 2010; 101(6): 2026– 33.

14. Zulkifli R, Zulkarnain, Mohd Nor MJ. Noise control using coconut coir fibers sound absorber with porous layers backing and perforated panels. American Journal of Applied Sciences. 2010; 7(2): 260–4.

15. Ali A, Shaker K, Nawab Y, Jabbar M, Hussain T, Militky J, et al. Hydrophobic treatment of natural fibers and their composites—A review. Journal of Industrial Textiles. 2018; 47(8): 2153–83.

16. Gusti I, Sudipta K, Sudarsana DK. Permeabilitas beton dengan penambahan styrofoam. Jurnal Ilmiah Teknik Sipil. 2009; 13(2): 192–8.

17. Sinarep, Catur AD, Hafidzul M. Redaman suara pada komposit sandwich polyester berpenguat serat sisal dengan core styrofoam. Dinamika Teknik Mesin. 2014; 4(1): 30-7.

18. Novak C, Kunio J. Comparative Study of the ASTM E1050 Standard for Different Impedance Tube Lengths. Noise-Conference 2011. 2011; 1–9.

19. Mediastika CE. Kualitas akustik panel dinding berbahan baku jerami. DIMENSI-Journal of Architecture and Built Environment. 2008; 36(2): 127–34.

20. Pratama A, Karo-Karo P, Sembiring S. Pembuatan dan karakterisasi komposit batako ringan dengan campuran sekam padi sebagai bahan pengisi untuk konstruksi bangunan redam suara. Jurnal Teori dan Aplikasi Fisika. 2014; 2(1): 49–57.

21. Zunaidi NH, Tan WH, Majid MSA, Lim EA. Effect of physical properties of natural fibre on the sound absorption coefficient. Journal of Physics: Conference Series. 2017; 908(1): 1-6

22. Mahzan S, Zaidi AM, Arsat N, Hatta MNM, Ghazali MI, Mohideen SR. Study on sound absorption properties of coconut coir fibre reinforced composite with added recycled rubber. International Journal of Integrated Engineering. 2010; 2(1): 1–6.

23. Zulkifli R, Nor MJM, Ismail AR, Nuawi MZ, Abdullah S, Tahir MFM, et al. Comparison of acoustic properties between coir fibre and oil palm fibre. European Journal of Scientific Research. 2009; 33(1): 144–52.

24. Sathishkumar TP, Navaneethakrishnan P, Shankar S, Rajasekar R, Rajini N. Characterization of natural fiber and composites - A review. Journal of Reinforced Plastics and Composites. 2013; 32(19): 1457–76.

25. Peng L, Song B, Wang J, Wang D. Mechanic and acoustic properties of the sound-absorbing material made from natural fiber and polyester. Advances in Materials Science and Engineering. 2015; 2015: 1–5.

26. Patnaik A, Mvubu M, Muniyasamy S, Botha A, Anandjiwala RD. Thermal and sound insulation materials from waste wool and recycled polyester fibers and their biodegradation studies. Energy & Buildings [Internet]. 2015; 92: 161–9. Available from: http://dx.doi.org/10.1016/ j.enbuild.2015.01.056

27. Ahmad F, Choi HS, Park MK. A review: Natural fiber composites selection in view of mechanical, light weight, and economic properties. Macromolecular Materials and Engineering. 2015; 300(1): 10–24.

28. Arenas J, Crocker M. Recent trends in porous sound-absorbing materials. The Noise and Vibration Control Magazine. 2010; July: 12–7.

29. Park J, Yang SH, Minn KS, Yu C Bin, Pak SY, Song YS, et al. Design and numerical analysis of syntactic hybrid foam for superior sound absorption. Materials and Design. 2018; 142: 212–20.

30. Sinarep, Catur AD, Hafidzul M. Redaman suara pada komposit sandwich polyester. Jurnal Dinamika Teknik Mesin. 2014; 4(1): 30–7.

31. Bujoreanu C, Nedeff F, Benchea M, Agop M. Experimental and theoretical considerations on sound absorption performance of waste materials including the effect of backing plates. Applied Acoustics [Internet]. 2017; 119: 88–93. Available from: http://dx.doi.org/10.1016/j.apacoust.2016.12.010

32. Ia nicu I, Vasile O, Iatan R. The analysis of sound-absorbing performances for composite plates containing recycled textile wastes. UPB Scientific Bulletin, Series D: Mechanical Engineering. 2016; 78(1): 213– 20.

33. Hays J, McCawley M, Shonkoff SBC. Public health implications of environmental noise associated with unconventional oil and gas development. Science of the Total Environment. 2017; 580: 448–56.

34. Roswall N, Høgh V, Envold-Bidstrup P, Raaschou-Nielsen O, Ketzel M, Overvad K, et al. Residential exposure to traffic noise and health-related quality of life-A population-based study. PLoS ONE. 2015; 10(3): 1– 13.

35. Hong JY, Jeon JY. The effects of audio-visual factors on perceptions of environmental noise barrier performance. Landscape and Urban Planning. 2014; 125: 28–37.

Recommended Citation

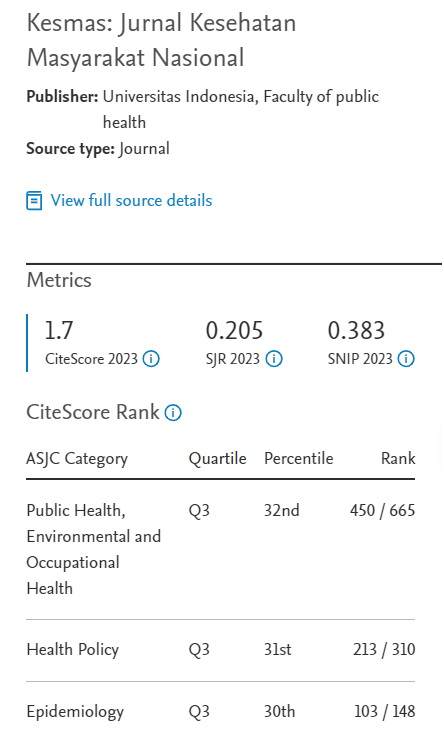

Nasri SM , Shofwati I .

Utilization of Styrofoam as Soundproofing Material with Auditory Frequency Range.

Kesmas.

2018;

13(2):

99-104

DOI: 10.21109/kesmas.v13i2.2633

Available at:

https://scholarhub.ui.ac.id/kesmas/vol13/iss2/9

Included in

Biostatistics Commons, Environmental Public Health Commons, Epidemiology Commons, Health Policy Commons, Health Services Research Commons, Nutrition Commons, Occupational Health and Industrial Hygiene Commons, Public Health Education and Promotion Commons, Women's Health Commons